Basic seal joint types

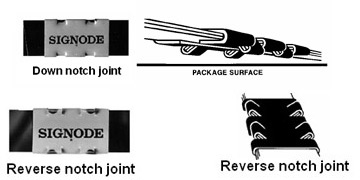

Notch joint

One way to lock strap ends is to press, or “Notch” the seal and the strapping it joins to form tabs at the edges. These tabs are bent down (regular) or bent up (reverse). The strength of the notch-joint comes from the mechanical interlock between the seal and the strapping. Notch-joints are typically used on waxed strapping in packaging and unitizing applications.

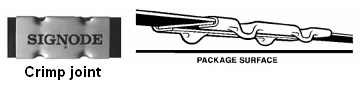

Crimp joint

Another way to seal the ends of strapping is to press, or “Crimp” undulations into the seal and strapping ends. The strength of crimp-joint comes from the deformed seal creating high frictional forces. Crimp joints produce high static and dynamic joint strengths and are used on applications like car loading, where the strapped load is subjected to severe impact.

Sealless joint

Sealless joint can be made with Signode manual or pneumatic combination tools. Sealless joints do not require the use of metal seals and provide static joint strength equivalent to Notch-type joints.

Steel Strapping

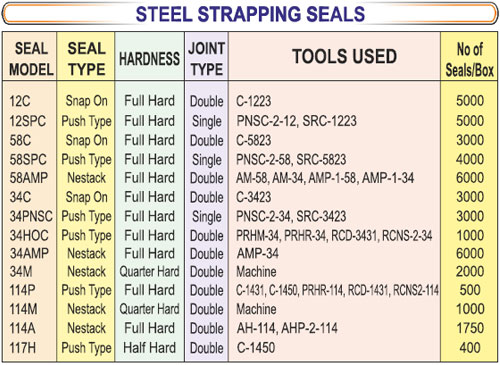

Placed over the overlapping strap ends either during or after tensioning the strapping. Eliminates pre-threading. Speeds the strapping operation.

Catalogue

Held together by interlocking nibs. This Signode development permits loading partial stacks into magazines of seal feed combination tools and power strapping machines

Catalogue

Must be threaded over the overlapping strap ends before the tensioning tool is applied. Generally used on bales, bundles and the larger strap sizes.

Catalogue

Used where strap is tensioned by butting the nose of the tensioner against the seal. Overlapping flanges withstand the higher stress.

Catalogue

For severe impact applications using waxed strapping. Microgrip seals are coated inside with a high-friction grit which bites through the wax to provide maximum holding power.

Catalogue